Jason Sandefur

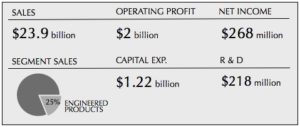

Alcoa”s Engineered Solutions segment, including fasteners, recorded a 9.7% gain in sales to $5.04 billion in 2005, while operating income for the year declined 7% to $196 million on increased raw material costs and operating losses.

in 2005, while operating income for the year declined 7% to $196 million on increased raw material costs and operating losses.

“In aerospace, both our Howmet and Alcoa Fasteners businesses experienced strong sales and margin growth during the year, as the aerospace market surged,” stated CEO Alain Belda in the company”s annual report.

Alcoa Fastening Systems highlights for 2005 include a decision to create two new 50,000 square-foot manufacturing sites in China to support rapidly growing commercial aviation and

railway/rail car  production and sub-assembly in the region. The factories will be located in the Suzhou Industrial Park about 60 miles from Shanghai.

production and sub-assembly in the region. The factories will be located in the Suzhou Industrial Park about 60 miles from Shanghai.

The facilities are expected to employ a minimum of 250 workers by 2007.

AFS also opened a full service logistics center in Shanghai in the first half of 2005 (see 5/12/05 issue of FIN).

Anne Brown, communications manager for AFS” aerospace products, said the expansion does not signal a move away from U.S. production.

“Because the aerospace market is growing rapidly, Alcoa Fastening Systems is adding capacity in many of our current facilities and also in new facilities in Mexico and China to grow with the market and help meet our customers rapidly increasing demands,” Brown told FIN.

Domestically, AFS opened a commercial products distribution center in Indianapolis, IN. The 10,000 sq ft facility will serve the Midwestern markets for all AFS brands, including Huck, Recoil and Marson. AFS” distribution center in Carmel, IN, was consolidated into the new facility. The facility address is 5436 W. 78th St., Indianapolis, IN, 46268. Tel: 800 732 3470

In 2005 Lockheed Martin selected AFS to provide millions of high-performance fasteners plus advanced installation systems for its military aircraft programs through 2010.

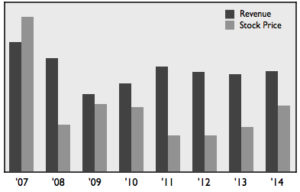

Parent company Alcoa saw record revenue in 2005, with sales climbing 13% to $26.2 billion. However profit dipped 5.9%, hit by rising energy and input costs.

Aluminum-giant Alcoa entered the fastener industry with the 2000 acquisition of Cordant Technologies Inc., which included Huck. Huck had acquired fastener manufacturer Jacobson Mfg. Co. Inc. in 1998 and Chicago-based Continental/Midland Group in 1999. Alcoa acquired Fairchild Fasteners in 2002 for $655 million, and then combined the company with Huck International to form Alcoa Fastening Systems.

In 2004 AFS partnered with Airbus to help create the A380, the largest airliner ever built. Assembled using 1 million aluminum rivets and other fasteners supplied by AFS, the 260-foot-long A380 will carry as many as 800 passengers on two decks.

Alcoa Fastening Systems” plants in Tucson, AZ, and Carson, CA, have been certified AS9100/ISO 9001 (quality), ISO 140001 (environmental) and OHSAS 18001 (health and safety). The Carson and Tucson plants are the first AFS facilities to achieve triple certifications.

Headed by former Fairchild Fasteners chief Olivier Jarrault, AFS operates 26 facilities in the U.S., Europe, Mexico and Australia.

AFS employs 6,500 people in two divisions: aerospace products and commercial products. The company is headquartered at 3000 W. Lomita Blvd., Torrance, CA 90505. Tel: 805 527-3600 Fax 805 991-1449 Web: alcoafasteners.com

Corporate Office: 201 Isabella St., Pittsburgh, PA 15212-5858. Tel: 412 553-4545 Fax 412 553-4498

Web: alcoa.com

NYSE Symbol: AA

CEO: Alain Belda, 62

Key fastener executives: Olivier Jarrault, president, Alcoa Fastening Systems; Don Busby, president, commercial products; Richard Sharpe, AFS senior vice president for aerospace customers and marketing; Jim Doran, AFS regional sales manager

Founded: 1888Employees: 129,000 \ �2006 FastenerNews.com

Share: