Additive manufacturing, also known as “3D printing,” is gaining ground in the fastener industry.

Additive manufacturing, also known as “3D printing,” is gaining ground in the fastener industry.

In recent weeks, two prominent fastener companies have announced programs to add upgraded 3D printing to their businesses.

Bossard Group, together with its subsidiary KVT-Fastening, will presented three different technologies at the Additive Manufacturing Expo in Lucerne from in early March.

Cooperation partners for the Swiss market include TRUMPF (laser metal fusion), German RepRap (fused filament fabrication) and Henkel (stereolithography). These partnerships will allow Bossard to sell 3D industrial printers and related consumables (metal powder, filaments, etc.). Bossard will also act as a partner in consulting customers up to designing complex parts for 3D printing.

“The Bossard Group views 3D printing as a forward-looking technology that will transform some areas of industrial manufacturing. Our involvement relies on partnerships with three manufacturers of premium industrial 3D printers and related technical support services.”

In cooperation with its partners, the Switzerland-based company will expand the new 3D printer line. The devices are based on three different technologies and are designed for professional use in various areas, including product development, prototyping, model- and mold-making, architecture, product design, and creation of complex components with functional integration. Web: Bossard.com

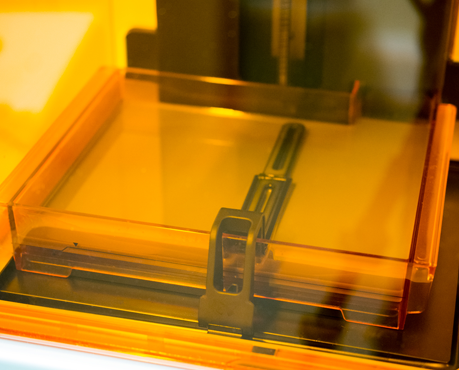

Likewise, UK-based TR Fastenings invested in a new 3D printer – an SLA (StereoLithic Apparatus) machine that delivers superior quality to the FDM (Fused Deposit Modeling) equipment replacing the existing model.

Until recently, SLA printing was prohibitively expensive, but after a group of American MIT students designed and received funding for the ‘Form 1’ model, costs reduced. The Form 1 machine has now been replaced by the Form 2 model, which TR has purchased.

“While most of the components supplied by TR to its customers are metal, plastic prototypes are ideal to check the form rather than the function of a part,” TR Fastening stated.

The printer will be used to create these prototypes for TR customers who want to explore new variations on existing parts or components used in their production process.

“The TR team will use its extensive library of CAD designs along with the printer’s sophisticated software to create variations of different fasteners for customers to view and test.”

Keith Gibb, Head of Web Development at TR, comments: “We first invested in 3D printing technology 3 years ago by purchasing the FDM machine, which is simple to use and ideal for our first foray into the process but doesn’t produce the best quality parts.

“The speed and accuracy of the new printer has already allowed us to produce prototypes for a number of customers in both the automotive and electronics sectors. We made plastic prototypes of metal parts which meant one customer could check fit and form of a new part in 3 days rather than laying down expensive tooling and waiting for weeks. We’ve also produced fully working prototypes of injection moulded parts that were with the customer in 24 hours – the actual injection moulded samples would have taken 6 weeks.” Web: trfastenings.com

Share: