4/27/2012 12:55:00 AM

NEWS BRIEFS

Airbus Cuts A380 Build Rates To Fix Fastener Cracks

![]()

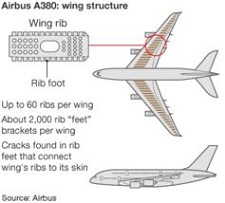

Airbus intends to cut A380 production rates by 15% to deal with micro cracks appearing in wing brackets and fasteners, La Tribune reports.

By reducing production from 2.7 aircraft per month to 2.3, Airbus will build time in its production schedule to modify the aircraft’s wings, addressing the problem at the A380 wing facility in Broughton, UK.

The modification will cost an estimated EUR 105 million and take as many as eight months to complete.

Airbus reportedly expects to deliver 30 A380s in 2012, up from the 26 delivered in 2011, according to La Tribune.

In February the European Aviation Safety Agency (EASA) directed Airbus to replace some aluminum rivets on its A380 flagship withstronger titanium fasteners.

An engineering review determined that six aluminum rivets — used at the junction of fuselage stringer (STGR) 21 Left Hand (LH) and Right Hand (RH) and frame (FR) 0 — do not comply with certification requirements.

“Fatigue analysis has shown that while at STGR21 junction with FR0, the structure Limit Load capability is still ensured, it may not support Ultimate Load,” the EASA stated in an Airworthiness Directive.

If not corrected, this condition could lead to in-flight loss of the radome in case of rapid decompression and could adversely affect the structural integrity of the jet.

The AD requires the replacement of the affected six aluminum rivets with six hi-lite titanium fasteners. The repair came in response to the fleetwide inspection of all Airbus A380 superjumbos following the detection of cracks in the wings of several aircraft.

Cracks were first discovered in December on an A380 that was being repaired after an engine explosion in Singapore. The cracks reportedly were attributed to the manufacturing process used at Broughton, where the wings are made.

“This manufacturing process may be related to the combination of the use of “interference-fit” fasteners (where the hole is slightly smaller than the fastener diameter) and the loads being applied when the wing skin is attached to the wing,” The Conversation reports.

“If the high loads being applied to the fasteners during assembly are not adequately accounted for, they will combine with the stresses arising from the interference fit, potentially leading to cracking.” ©2012 GlobalFastenerNews.com

Related Stories:

• “Lack” of Fasteners Blamed for Cincinnati Casino Collapse

• Alcoa Fastening Systems Segment Hits Record Revenue

Share: