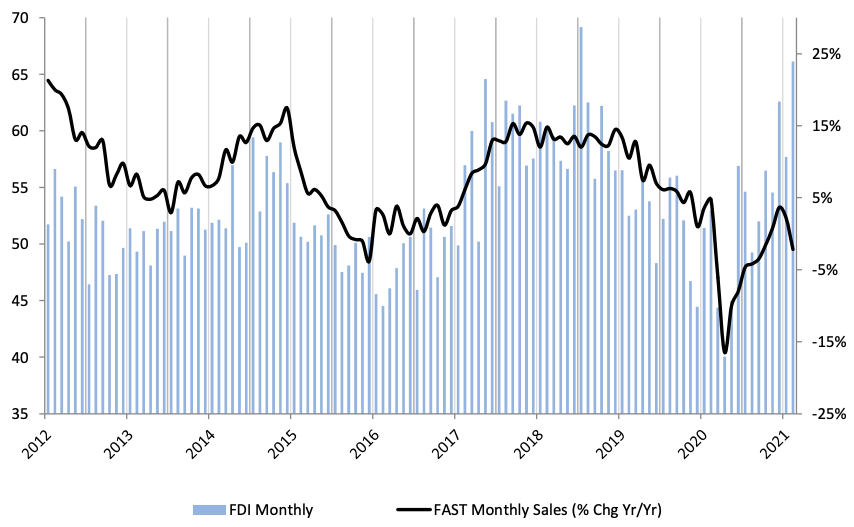

The Fastener Distributor Index (FDI) rose to 66.1 in February from 57.7 in January.

“A robust 69% of respondents saw better than seasonally expected sales in February, which is consistent with levels seen over the last three months,” according to R.W. Baird analyst David Manthey. “Inflationary pressures, particularly in steel and freight costs, continue to be felt by many respondents. Additionally, supplier lead times remain very extended, leaving some respondents concerned about their ability to meet future demand.”

The seasonally adjusted FLI surged to 73.9 from 66.7 last month, marking a record for the index. All four components of the FLI (employment, respondent inventories, customer inventories, and six-month outlook) increased.

A record 69% of respondents consider customer inventory levels to be currently too low, implying some restocking is needed ahead, which should be bullish for future demand conditions, Manthey reports.

“With the FLI well above 50, customer inventories getting increasingly low, and respondents continuing to forecast favorable six-month outlooks, we believe the FDI should see additional expansionary readings ahead, implying continued improvement particularly as y/y comparisons ease significantly next month.”

Employment levels were slightly higher m/m.

The FDI employment index registered a 67.1 reading this month vs. 64.3 last month. More than 40% of respondents saw employment levels as above seasonal expectations in February compared to 34% in January.

“Looking at the broader economy, despite a continued gradual recovery in the labor market, the unemployment rate remains elevated (6.3% as of January), and even more so when including discouraged and part-time workers (11.1% unemployment),” Manthey writes.

Supply chain constraints remain key area of focus for respondents.

“For the second consecutive month, nearly every comment touched on raw material inflation and logistics issues,” according to Manthey. “Congestion at the ports, container shortages, and weather challenges are causing significant logistics disruptions.”

Per one respondent: “FedEx and freight companies lost some big shipments, otherwise we would have been much higher. Blaming the icing to the Midwest as the reason why and oh yeah, China virus too.”

Rapid spikes in raw material inflation also continues to cause headaches for many respondents.“Material price spikes [are] unreal, in some cases 30-60% higher,” stated one respondent. “Freight costs from overseas continue to be as challenging as [is] getting product out of the port in Long Beach. Lead times are climbing as overseas is bombarded with orders from the Big Boys, and domestic supplier lead times are skyrocketing due to [an] influx of business and suppliers covering the gap from overseas.

“Meanwhile getting material pricing domestic can take up to two weeks due to shortages. Quite a mess right now.”

Another respondent noted: “Steel is getting more expensive and much more difficult to get. Supply vs demand is a genuine concern.”

Manufacturers continue to struggle in meeting the elevated demand.

The FDI is a monthly survey of North American fastener distributors conducted by the FCH Sourcing Network, the National Fastener Distributors Association and Baird. Web: fdisurvey.com

Share: