4/26/2011 11:09:00 AM

NEWS BRIEFS

Report: Ruptured Southwest Jet Had Rivet Manufacturing Flaws

![]()

The National Transportation Safety Board released its interim report on the April 1, 2011 accident involving Southwest Airlines flight 812 that experienced a rupture in the fuselage while in flight.

Following an emergency landing at the Yuma International Airport in Arizona, the aircraft was inspected by NTSB investigators, who found “an approximately 9-inch wide by 59-inch long rectangular-shaped hole in the fuselage crown on the left side of the airplane, aft of the over-wing exit.”

Portions of the fuselage skin totaling 116 inches by 19 inches were removed from the aircraft and transported to the NTSB Materials Laboratory in Washington, DC. The samples included the rupture and a second section “located forward of the hole.”

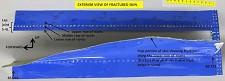

Microscope examination of the fracture faces of the ruptured skin revealed fatigue cracks emanating from at least 42 of the 58 rivet holes connected by the fracture, the agency stated.

“Non-destructive eddy current inspections conducted around intact rivets on the removed skin section forward of the rupture revealed crack indications at nine rivet holes in the lower rivet row of the lap joint,” the report stated.

“To assess the condition of the intact rivets and the skin rivet holes, X-ray inspections were performed on the skin located forward of the rupture location. This inspection revealed gaps between the shank portions of several rivets and the corresponding rivet holes for many rivets associated with S-4L.”

“Upon removing selected rivets, the holes in the upper and lower skin were found to be slightly offset relative to each other and many of the holes on the lower skin were out of round.”

In this ongoing investigation, the NTSB Materials Laboratory work is actively conducting additional inspections and examinations in the following areas:

Removal of rivets and examination of rivet hole dimensions, rivet dimensions, and rivet hole alignment between upper and lower skins.

Detailed fractographic analysis of the skin fractures emanating from the rivet holes using optical and scanning electron microscopes.

Fatigue striation analysis using a scanning electron microscope of specific skin fractures to determine the rate of crack propagation.

Additional portions of the lap joints from the accident aircraft.

Electrical conductivity measurements, hardness tests, and X-ray energy dispersive spectroscopy elemental analysis of the skin in the area of the fracture revealed that the aluminum skin material was consistent with the specified material. The skin was the specified thickness.

The NTSB described the rupture as “an approximately 9-inch wide by 59-inch long rectangular-shaped hole in the fuselage crown on the left side of the airplane, aft of the over-wing exit.”

“The 59-inch longitudinal fracture occurred in the aluminum fuselage skin along the lap joint at stringer-4 left (S-4L) between body station (BS) 666 and BS 725. At S-4L, the crown skin overlaps the lower skin forming a lap joint. The two skins are connected at the lap joint by three rows of rivets (referred to as lower, middle, and upper row of rivets.)”

The fracture was through “the lower skin and connected 58 consecutive rivet holes in the lower row of lap joint rivets.”

“The exterior surface of the skin in the area of S-4L is painted blue. Evidence of blue paint was also found inside the joint between the upper and lower skin and on several areas of the skin fracture surface.”

The incident occurred during Southwest Airlines flight 812, when a Boeing 737-300 (registration N632SW) experienced a rapid depressurization caused by a rupture in the fuselage at 34,000 feet.

The flight crew conducted an emergency descent and diverted the flight to Yuma International Airport, Yuma, AZ.

At the time of the accident, the aircraft had accumulated 48,740 hours of service and 39,781 cycles, the NTSB said.

The aircraft was delivered to Southwest Airlines on June 13, 1996.

The NTSB is continuing its investigation. ©2011 GlobalFastenerNews.com

Related Stories:

Share: