4/10/2013 5:17:00 PM

HEADLINES

Officials investigating the 32 snapped anchor rods on the new $6.4 billion eastern span of the Oakland Bay Bridge have narrowed their focus to two “distinct” batches of bolts manufactured by Ohio-based Dyson Corporation.

One batch included a total of 96 rods manufactured and installed in 2008. The “failed bolts” came from that batch, which was encased in concrete as part of shear key construction.

A second batch of anchor rods, totaling 192, are through bolts manufactured in 2010 and installed in 2011.

Those two batches of anchor rods – ranging from 9 feet to 24 feet in length – are at the center of an investigation into how specialty bolts from a respected domestic manufacturer failed within days of coming under load on a major U.S. bridge.

Bridge officials discussed their findings at a Bay Area Toll Authority (BATA) Oversight Committee meeting held on April 10 in Oakland, CA. FIN covered the meeting via an online audio feed.

2008 Bolts

The bolts that fractured lay encased in concrete for several years but could “not be stressed until completion of load transfer” on the bridge. On March 1, 2013, construction crews torqued the nuts for the rods.

“Within a very short period of time we started discovering fractured rods,” noted toll bridge program manager Tony Anziano.

Three days to be exact. That’s when the first bolts fractured, according to California Department of Transportation records. The vast majority of the bolts fractured on days 6 and 7, with new fractures discovered until day 14 when the remaining 64 anchor rods were detensioned.

At the April 10 meeting Anziano said workers have extracted four of the failed rods so far, and all four had fractured near the bottom of the rod “at the first thread above the nut.”

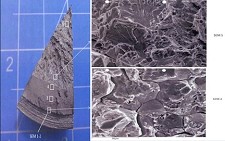

Anziano described the fractures as having a “darker, flatter crescent moon shape” — an important indicator of where the fractures began.

Following the fractures, bridge officials launched a forensic analysis with electron microscopy and mechanical property tests to probe the problem. Those tests revealed “geometric shapes with actual spaces between them, which is fairly strong evidence that there was hydrogen in the rods which produced this fracture.”

Anziano pointed out that hydrogen contamination can occur post-production, leaving officials unsure at this point exactly when hydrogen was introduced into the steel.

“We had a hydrogen problem with the 2008 bolts,” he said. “It could have occurred in the manufacturing process, or it could have occurred after the bolts were embedded and exposed to water.”

“It’s important to remember that water is H2O. Hydrogen is a component of it.”

Officials also combed through extensive quality control and quality assurance documentation to ascertain what might have gone wrong.

Documents from the 2008 batch revealed two non-conformance reports. One involved a paperwork problem (materials were sent for delivery ahead of documentation) that was quickly remedied. The second NCR “related to the test results for two components of the 2008 rod assemblies: hardness of the nuts and elongation of the rods.”

Out of more than 150 individual rod results obtained from both quality control and quality assurance testing, only five results were below specifications. All five involved one mechanical property — elongation.

“The specification requires a minimum of 14% elongation, and 5 results were in the range of 12.5-13.6%, or 1.5 – 0.4% below specification.”

Those 2008 test results were reviewed by design and construction engineers and the material was determined to be suitable for use.

The remaining 192 rods for other shear keys and bearings were manufactured in 2010. All of those rods passed QC/QA testing.

As of April 9, those rods have been tensioned to about 70% of maximum load. All of them have been visually inspected and “there’s been no indication of a problem,” according to Andrew Fremier, deputy executive director of the Bay Area Toll Authority (BATA).

Of the 2010 batch, ten rods have been selected for instrumentation to monitor bolt performance. An additional ten will be removed for destructive testing.

Solutions

Officials at the meeting said they are exploring a two-part solution.

The first involves retrofitting the shear key where the embedded bolts failed. One retrofit idea design engineers are exploring involves placing a steel collar around the base. Theoretically they could also replace the embedded bolts, though officials quickly pointed to significant problems involving rebar congestion and accessibility.

The second part of the solution is the continued monitoring of the 192 through bolts from the 2010 batch to determine whether or not they should be replaced. Officials expressed cautious optimism that they won’t encounter hydrogen problems with those bolts, but indicated they are exploring what it would take to replace them.

Anziano noted that supply chain issues exist for a rapid turnaround. Fastener manufacturers are booked up at the moment, he said, making it likely that the bridge authority will have to pay a premium to secure an order.

“You just can’t go down to Ace Hardware for these things.” ©2013 GlobalFastenerNews.com

FIN’s Background on Dyson

Founded in 1884 as a specialty forging shop in Cleveland by Joseph Dyson, today Dyson is a ISO 9000 certified manufacturer of fasteners for the nuclear, bridge, mining, military, locks and dams, oil and gas and wind power markets. Dyson provides custom forging, machining, heat treating, inspection and quality control.

Dyson manufactures bolts and screws, nuts and washer, rods, studs, pins, construction accessories, specialty fasteners, custom forging and machining to ASTM, SAE, ASME, MIL/Federal, ISO, ANSI, AASHTO and DIN specifications.

Dyson exports fasteners to Europe, Africa, the Middle East, Asia, Australia, Canada and Mexico.

In 2010 Dyson was awarded a contract for bolts, nuts, washers and plate assemblies for the rewrapping of the main cable and hand rope replacement on the rehabilitation of the 1909 Manhattan Bridge. The bridge carries vehicular, mass transit, pedestrian and bicycle traffic.

“With in-plant capabilities that range from open or closed die forging and heat treating, to primary and secondary machining, and strict quality control, Dyson can assure you of unsurpassed quality because we control every facet of the manufacturing process,” according to the company’s website – dysoncorp.com.

See FIN Fastener History:

1988 FIN – Dyson Introduces Traceable Bolts

1984 FIN – Dyson Completes U.S. Navy Construction Requiring Large Fasteners

Related Stories:

• Nucor Fastener Antidumping Case Moves Forward

• Screw Products Expanding Stainless Lines

Share: