HEADLINES

U.S. Forest Service Looking for Fastener Partners

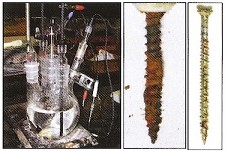

L to R — Electrochemical test cell, polymer coated fastener exposed to wood extracts, electroplated fastener after exposure in solid wood (courtesy USDA Forestry Service)

The Forest Products Laboratory of the USDA Forest Service is looking for fastener manufacturer and testing laboratory partners for measuring the surface area of threaded and non-threaded fasteners.

The tool, invented by Douglas Rammer, P.E., and Samuel Zelinka, PhD, improves determination of fastener corrosion from treated wood and necessary replacement rates. It also helps metal plating companies determine the surface area of a threaded fastener prior to plating. Fastener manufacturers can incorporate algorithm into existing manufacturing equipment, improve production control and improve quality.

Rammer explained that accurate measurement of the surface area of threaded fasteners is important for understanding the behavior of fasteners in applications such as corrosion rates for fasteners in contact with treated wood and metal plating of threaded fasteners.

The patented measuring tool uses an optical method and apparatus to determine the surface area of fasteners from high-contrast digital images.

The images of the fastener are separated into regions to determine corresponding surface area.

For licensing information contact Janet Stockhausen, USDA Forest Service. Tel: 608 231-9502 E-mail: jstockhausen@fs.fed.us ©2011 GlobalFastenerNews.com

Share: